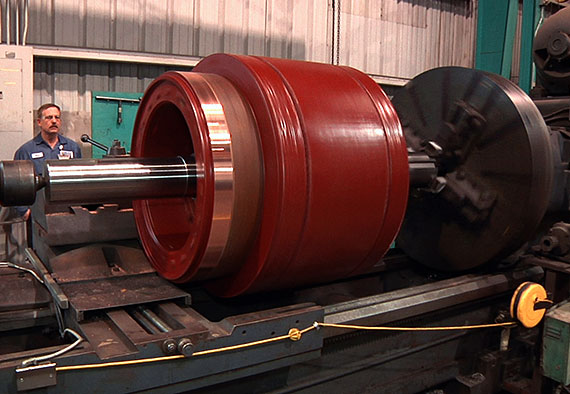

Bradleys offers quality electric motor repair, rewinding, and horizontal and vertical motor load testing for small to ultra large motors at value-added rates, with quick turnaround to minimize downtime.

We have provided electric motor repair, rewinding and load testing on some of the largest motors in the world, both on and offshore, for over 90 years.

Located in Gregory, TX, our state of the art, 110,000 sq. ft. facility is the largest, newest production shop of its kind in South Texas. Bradleys is ISO 9001:2015 certified, EASA Accredited and Green Motor Initiative Accredited.

Dedicated Project Managers are in constant communication with you, providing reports and photos daily as your project progresses through the repair process.

Bradleys’ has made significant investments to improve our quality, capabilities, processes, and efficiency. Our Management team is focused on monitoring and improving processes, efficiency, and communication with customers, along with quality, safety and the overall customer experience with Bradleys.